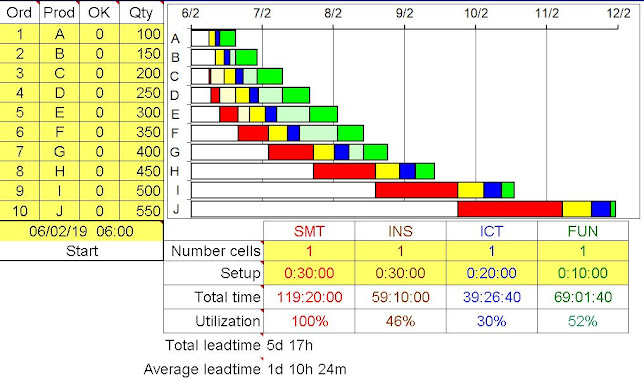

Production Scheduling

When we need to process different products in the same line we want to work out the best job sequence to minimize lead time and maximize capacity utilization. We also need to work out the minimum lot size to meet the demand and minimize lead time. Before we can commit the delivery date of a new job to the customer we need to know the state of the jobs already being processed For non repetitive processes you can use project management scheduling The ideal of "Lean Production" is lot size of 1 but this is not always possible when change-over time is significant. This change-over involves loading different components and changing jigs or molds. When change over or setup time is significantly higher than process time we are forced to work with larger lot sizes. One way to minimize lot size is to minimize setup time. The SMED (Single Minute Exchange of Dies) methodology has been very successful to reduce setup times from hours to minutes. Scheduling Constraints In a sequ...