Statistical Process Control with Excel

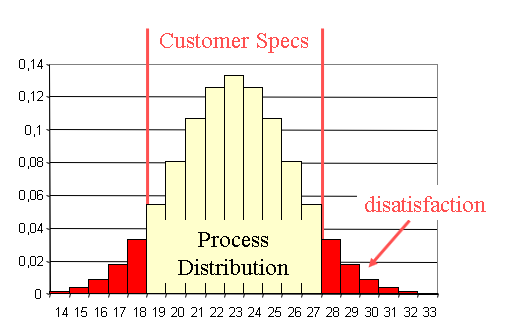

Statistical Process Control (SPC) is used to control a critical process output, acting on the factors affecting it, only when required. The purpose is to differentiate between a statistically significant change in the process, and common cause variation, because the actions required will be different. Process stability is a prerequisite for any further analysis. If a process is not stable, any conclusions you draw, can't be assumed to hold in the future. With SPC we check for process stability in the future. Control over-reaction A case of over-reaction is illustrated by the following example: Someone is shooting at a target, and based on the deviation of the impacts, he adjusts the gun site after each shot. The result will be an increase of the dispersion of the impacts; therefore, the adjustments will make the process worse. The correct way is, of course, to fire 5 or 6 shots without adjustments, and then decide if adjustment is required, based on the center of the impacts. ...