Value Stream Defect Generation and Detection

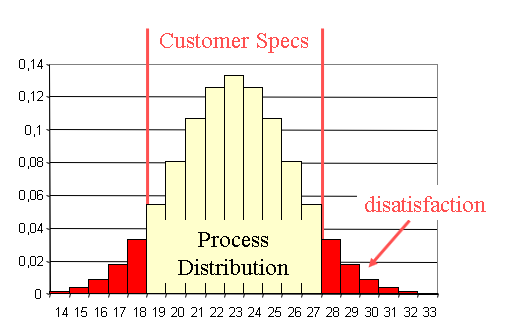

The quality level seen by the customer of our value stream is one of the most critical process metrics. This quality level is the result of all the defects generated by the different process steps as well as those coming from the parts suppliers. Ideally defects should not be produced in the first place. Unfortunately the state of the art, in many technologies, is still not there. Therefore, on the mean time, we need process tests and controls to catch and correct defects as soon as they are produced. In our Value Stream Map we focus on process flow but this flow is very much affected by quality. It is important to find out where in the process each type of defect is generated and where in the process it will be detected to make sure it doesn’t find its way to the customer. Control Plan The Control plan defines all the controls, visual, test, etc., installed along the value stream in order to catch the defects as soon as they are produced in order to correct them and give im...