Natural Gas Demand Forecast

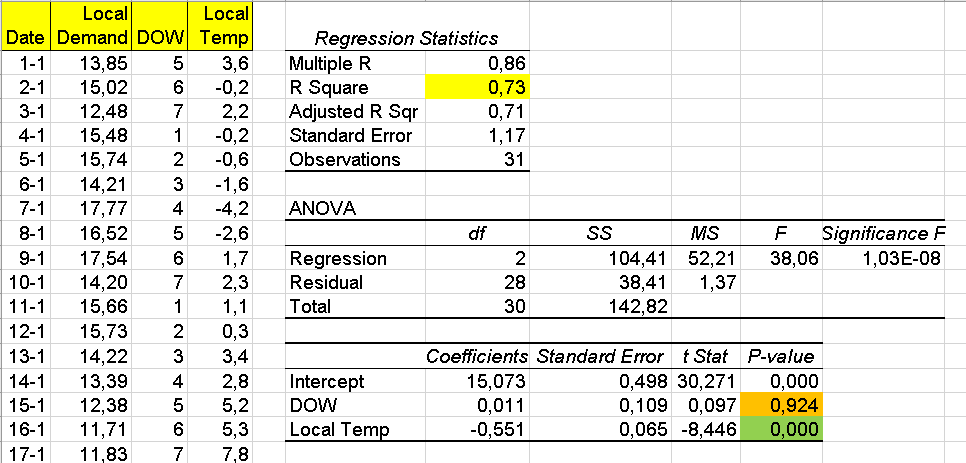

Natural gas demand is highly seasonal, therefore forecasting the final consumption is essential to manage the complete supply chain. Temperature is a main factor affecting home gas consumption for heating. We will analyse the correlation between gas consumption and temperature. Download this Excel file with examples to your PC from OneDrive: Gas Forecast.xlsx This chart of local consumption during a winter month, leads us to believe that one main factor in consumption is ambient temperature. This may be due to its wide use for heating. We can think of other factors that may affect consumption such as the day of the week so we will analyse this actual consumption data with these two possible factors. We obtain the day of the week with an Excel formula from the date. We can get the average temperatures of the corresponding geographical area during this period from AEMET (Agencia Estatal de Meteorología) in aemet.es Day of the Week Calculation We obtain the day of the week wit...