Design of Experiments (DOE) with Excel

Design of Experiments (DOE) is a very useful process improvement methodology.

Microsoft Excel has some powerful data analysis tools, which I have, successfully, used for DOE.

When it comes to analyzing cause and effect, we want to know what process factors affect our outputs.

Correlation and Regression could give us an indication of the main factors, and the extent they affect the outputs.

In some cases, there may be interactions among the different factors, or the mathematical relation between factors and outputs may not be linear.

In these cases, it is useful to run a systematic set of experiments, to test all possible combinations of factors, to relate them to the outputs.

Factorial Experiment Example

We want to minimize process loss, and after some brainstorming among the process specialists, we concluded that 5 factors may affect loss. Based on current factor levels, we have selected the following levels to experiment with:

Download this Excel file DOE_with_Excel.xlsm from OneDrive

Factorial Designs

Full factorial designs, are constructed simply counting in binary, to obtain all the different combinations of 0 and 1, for all factors. In our designs, we just replace 0 with -1, to meet the balance property.

See sheet Designs:

1/2 Fraction Design

See sheet Half fraction:

With our 5 factors, to run a full factorial set of experiments, we would need 2 ^ 5 = 32 experiments.

This could involve time and money, before we are sure that all factors really affect our process.

Therefore we might start with a subset, of the full factorial, as a detection experiment.

A 1/2 fraction will involve 1/2 the number of experiments: 16.

We can build a 1/2 fraction, 5 factor design, from a 4 factor full factorial:

We do this, by replacing the 4 factor interaction (which is very unlikely to happen) with the 5th factor (Flow). We construct, therefore, the Flow column, multiplying the other 4 columns.

Run the Experiments

Experiments Simulation

We have added 2 additional experiments, with the values called central points (all zeros) which will correspond (in uncoded values) to the average value of the high and low levels, in each factor.

We do this, to make a more robust design, without going all the way to the full 32 experiments.

The simulator has provided the process loss estimation outputs, for each experiment.

In the simulator, every time we press F9, a new set of experiments is run, giving (as in real life) different results.

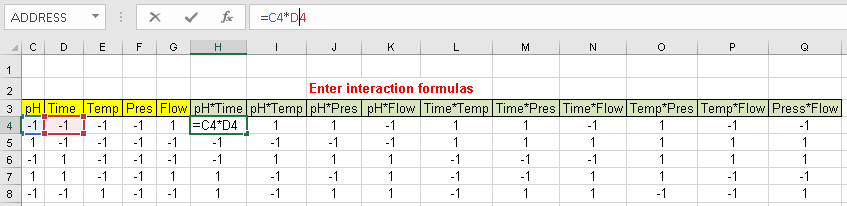

Factor Interactions

We want to be able to estimate the influence of each individual factor in the result, but also the interactions among them, so before we analyze the results we will build a column for each interaction among 2 factors.

If we wanted to include 3 factor interactions we would also add them to this matrix.

Sheet Detection:

You obtain each interaction column, just by multiplying the corresponding factor columns. Just enter the formula in the first line, and replicate all the way down.

Regression with Excel Data Analysis

Enter in Excel: Data/ Data Analysis/ Regression

And the result will be:

We notice that R^2 = 0.90 which validates our mathematical model.

The Probability column of the coefficients (p) tells us which factors and interactions are significant: those below 0.05.

Factors Temp and Press have a p value above 0.05 but their interaction is below (0.02) therefore we must keep them.

We run the Regression again keeping only the factors and interactions not removed (sheet Reduced model):

This equation is with factors in coded values.

Process Optimization

We now want to calculate, with this mathematical model of our process, which are the pH, Temp and Pres values which will minimize Process Loss.

In order to do this we will use Excel Solver. (See Theory of Constraints )

We will ask Solver to give us the values for the yellow cells.

We now call Solver to minimize this value in M23, changing pH, Temp and Pres with the restrictions that they must be between -1 and +1.

Temp = 150 (coded 1)

Pres =1 (coded -1)

Confirmation Experiments

We would now run confirmation experiments to validate these optimal values.Graphical Representation

We can view a graphical representation of our mathematical model to help us understand the process behavior:

Entering a value for pH we can see the Loss for each Press-Temp combination.

With the color code we clearly identify the minimum value in dark green: 7.6 which corresponds to Press = -1 and Temp = 1 as calculated by Solver.

3D Representation:

We can show the same data, with a 3D representation, in Excel

In spite of the curvature of this shape, the behavior of each factor is linear.

The twisting of the shape, is due to the interaction, between Pressure and Temperature.

Residuals Analysis to Validate the Model

We want to estimate the error we make, by replacing our process behavior, with this mathematical model. See sheet Residuals:

We subtract the actual Loss values, measured in our process, from the estimates of our formula, to obtain the residuals.

Test for Normality of the Residuals

The next check, is to make sure that the average of the residuals, is close to 0. Also that the residuals, follow a normal distribution (see sheet Normality):

If the P value, for this normality check, was below 0.05, this would indicate lack of normality.

Since it is 0.983, well above 0.05, it passes the test.

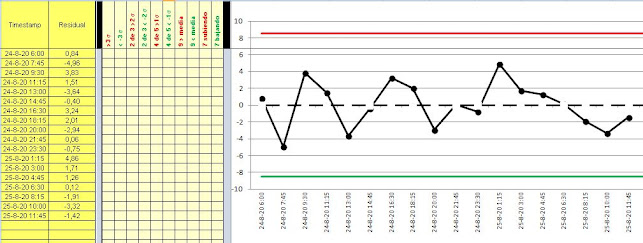

Test for Stability of the Residuals

See SPC Analysis

Conclusions

- Design of Experiments (DOE) is a powerful methodology, for process improvement.

- It enables the identification of critical process factors, based on data, rather than impressions.

- We can estimate the optimal values of these critical factors, to optimize the process.

- Excel provides some useful Data Analysis tools, to achieve this.

- Some processes outputs, don't have a linear relation with the critical factors. In this case we will need a more sophisticated formula such as RSM: Response Surface DOE with Excel

- Another non-linear example: The Catapult exercise

Comments

Post a Comment