Learn by Doing

The Socratic method helps students find solutions for themselves rather than just being told.

Group exercises and simulations are practical ways to implement this methodology.

In most value streams the delay between actions and effects is long (sometimes months) so it is difficult to associate results to some action we took in the past. Simulation reduces this delay from months to minutes so this allows us to try different solutions and experience the results and any side effects our actions may produce.

These are some successful group exercises and simulators:

The Beer Game

This is a group exercise which has been described by Peter Senge in The Fifth Discipline

It is very popular in management courses and it is a good example of learning by doing.

It simulates a beer supply chain from the factory to the final customer.

The objective is to meet the customer demand for a number of weeks keeping the minimum inventory level in the whole chain.

There are many learning experiences:

- Bullwhip effect: small demand fluctuations cause waves in the demand seen by the factory

- See the side effects of my actions to the whole chain

- Variation amplification due to long lead times

- Self inflicted problems caused by overreaction due to delay between action and response

- Effect of lack of real time data in the whole pipeline

- Temptation to blame others for the effects of our own actions

The Chair Exercise

In this exercise two teams compete to obtain the maximum profit by building paper chairs to satisfy the customer demand.

There is competitive bidding, based on cost and delivery time, to obtain each customer order.

During a training period they produce samples to understand the customer quality requirements.

One defect in one chair causes the rejection of the whole order. The order can again be submitted after correction.

Late deliveries (Vs committed time) are penalized.

Some learning experiences:

- Understand quality from the customer perspective

- Some process steps may require qualification: not anyone can do it

- Doing it right the first time is key

- Quick feedback of rejections to those causing them to change their process

- Clear definition of who does what and when: synchronization

- Due dates in mind by the whole team

- Competing with lead time may be more productive than competing with cost

The Effects of Variation: Experience Them Better Than Being Told

A dice throwing exercise is used to experience variation.

- Understanding the difference between random variation and trends is essential both for engineers and management.

- The actions required in one case and the other are different.

- The wrong actions could lead to overreaction and making the process worse

- Lack of reaction to slow trends may be just as bad

- Statistical Process Control will tell us if action is required

- Blaming people for variation they can't control only creates frustration

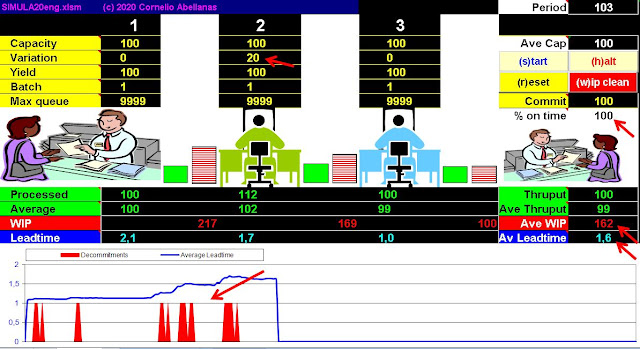

Not All Bottlenecks are Equal

- Different types of bottlenecks produce different effects in a value stream.

- What are the effects of capacity Vs yield bottlenecks?

- Variation bottlenecks, in particular, need simulation to experience their effects.

- A reduction of WIP may reduce lead time but will it also reduce throughput?

- Can Just In Time production cause throughput reduction?

- How will variation affect WIP, lead time and throughput?

- How may customer decommitments is my value stream likely to produce?

How Does Variation Affect my Value Stream? How About Simulation?

- Value stream simulation could help us understand its dynamic behavior taking into account real life variation

- We want to optimize resources while meeting the customer requirements: Where to reduce?

- Where is the bottleneck?

- What can we do to increase throughput?

- Is excessive accumulation of WIP causing excessive lead times?

- How can we reduce it?

There is a Delay Between Actions and Response in my Value Stream. How Does Auto-correlation Work?

- How to manage auto-correlation?

- What is the effect of overreaction in this case?

- Does it have a positive effect in some value streams?

- Does my body weight show auto-correlation?

Theory of Constraints Practical Examples

- Experience the importance of focusing on the bottleneck to achieve the objectives

- Try different scheduling plans to see the results and side effects

- Consider the various system constraints and their effects

- How does manufacturing lot size affect the results?

- Realize how some financial metrics may be inappropriate when constraints exist

- Practice system optimization with Excel Solver

Practice with Design of Experiments for Value Stream Optimization

https://polyhedrika.blogspot.com/2022/05/multiple-response-optimization-with.html

- Design of Experiments (DOE) is a practical methodology for process improvement

- After critical factors have been identified we want to find a mathematical formula that will relate these factors to results

- Simulation helps understanding how to design the experiments and interpret the results

- Excel data analysis helps in this interpretation

Conclusions

- Learning by Doing is a very effective way to teach both theory and practice

- Some experiences you never forget

- The Socratic method makes students find solutions for themselves rather than just being told

- Process simulation helps students find solutions for themselves and experience any side effects

- Students can try their own theories and compare the results

- Simulation, obviously, has some limitations: a mathematical model is a simplification of reality

Comments

Post a Comment